Brian Richardson

New member

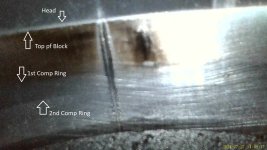

Had my plans changed for me this weekend when I found pretty significant gouge in the # 3 cylinder wall. The block is already overbored .040"(1mm). So I'm thinking maybe sleeve it and go back to .020"(0.5mm) over. Both 0.5mm and 1mm overbore are pretty common for available pistons.

Are there problems I'm not thinking about in sleeving a 8,000+ RPM engine?

Thanks!

Are there problems I'm not thinking about in sleeving a 8,000+ RPM engine?

Thanks!